Testing Lab and Contract Engineering Services

Senior Flexonics is one of the world’s leading organizations known for their Engineering and bringing innovative products to market for a wide range of industries. We also provide contract Engineering and testing for many companies that do not have their own testing facilities. Our testing lab operates independently from operations to ensure your confidentiality.

Test Lab Specifications:

- 24,000 square feet dedicated facility

- Cell type process flow

- Production representative equipment

- Full garage for on-vehicle instrumentation

- Capabilities and experience on both passenger car and large commercial vehicle

- Vehicle lifts for passenger cars

Key Test Equipment

Instrumentation:

- In-house FEA, CFD and customized heat transfer modeling

- Instrumentation

- Thermocouple

- Strain Gauge

- String Potentiometer (linear position sensory)

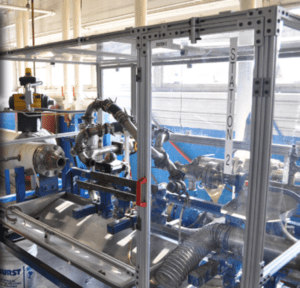

Thermal Flow Bench: 4 Test Rigs Available

- Temperatures up to 830 degC, at gas flow rates up to 25 kg/min

- Coolant side control up to 350 L/min at 4 bar pressure

- Air to liquid heat exchanger testing (Heated air and 50/50 ethylene Glycol)

- Utilized either for performance evaluation or durability test mode for long term thermal fatigue evaluation

Shaker Table: 2 Test Rigs Available

The testing lab utilizes two 3 Axis Electrodynamic Unholtz-Dickie 560B-16 shaker systems.

The testing lab utilizes two 3 Axis Electrodynamic Unholtz-Dickie 560B-16 shaker systems.

- Unit 1 features a slip table (shown)

- Unit 2 utilizes a pedestal mount

Shaker Table Capabilities:

- 200 “g” shock

- 2 inch (51mm) displacement

- 1,360 lbs automatic load support (618 kg)

MTS Low Frequency Testing: 7 Testing Stations Available

4 single axis

- 2 2 kip

- 1 3 kip

- 1 20 kip

- Load or displacement control

3 dual axis stations

- Both axis 2 kip

Capabilities:

- All stations can run under thermal (skin temperatures up to 870 degC / 160 deg F) and/or internal/external pressure load (up to 20 Mpa / 3000 psi)

- FlexTest 100 Digital Controller from MTS

Pressure Pulsation: 2 Testing Machines Available

Two purpose built pressure pulsation machines. MTS equipment can also be used for this purpose for additional capacity.

Unit #1 Capabilities:

Unit #1 Capabilities:

- Pressure up to 4000 bar at 15 hz frequency

- High pressure fuel testing

- Maximator PS1138

- One station but many parts can be tested in parallel

Unit #2 Capabilities:

- Frequencies up to 100 hz, pressures up to 35 bar

- Custom equipment

Pressure Burst:

Ideal for any high-pressure application.

Capabilities:

- Up to 6000 bar pressure capability

- Can be used for autofrettage on test samples as well